WELD-CHECK is a fully automatic system for non-destructive, contactless examination of welded joints of car bodies and sets new standards for testing accuracy and efficiency.

Quality Control with WELD-CHECK

Thermography for Fully-Automated Non-Destructive Testing of Car Bodies

Using pulse thermography, WELD-CHECK enables you a quantitative assessment of the inspected welds. A special software algorithm analyzes the pulse-induced change in temperature in the tested joint and computes, based on its temporal course and geometric spreading, corresponding test results. These results are documented in a test report and provided in a format that can be used in your quality databases. This makes WELD-CHECK the ideal test system for automobile body assembly - both as an offline measuring unit as well as for in-line inspection.

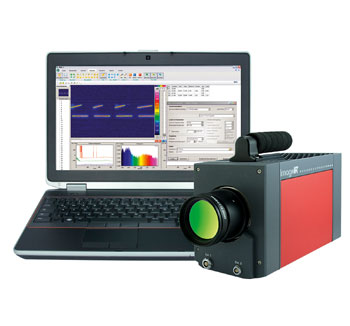

Thermal imaging cameras of the high-end camera series ImageIR ® by InfraTec are essential components used in this system. Enabling a geometric resolution of up to (1,920 × 1,536) IR pixels, frame rates with some kHz and thermal resolutions below 0,015 K they provide the precise measurement basis for the reliable detection of even the smallest anomalies.

WELD-CHECK Software